Address

Unit 4, No.9035 Zhufeng Road, Fengjing Town, Jinshan District, Shanghai

Email

sales@jsattachments.com

Address

Unit 4, No.9035 Zhufeng Road, Fengjing Town, Jinshan District, Shanghai

Email

sales@jsattachments.com

Hydraulic Hammers, also known as hydraulic breakers, rock breakers, etc. are powerful excavator attachments used to break down hard surfaces like concrete, asphalt, and rocks.

Applications:

Hydraulic breakers can be used in various heavy-duty tasks with different types of chisels. Here are some applications:

Types of Hydraulic Rock Breakers

There are 3 main types: Side Type, Top Type, and Silence (Box) Type. Different types are designed for specific applications with different advantages in terms of performance, durability and maintenance.

Side Type Hydraulic Hammer

Features flexibility and ease of use. It is perfect for applications that require maneuverability.

Best for: General demolition, trenching, and rock breaking in confined spaces.

Top Type Hydraulic Hammer

It’s ideal for projects demanding higher impact force and greater durability.

Best for: Large-scale excavation, foundation work, and breaking through tough rock formations.

Silence Type Hydraulic Hammer/Box Type Hydraulic Breaker

When the project is in the downtown, the noise control becomes quite important. Then the Silence Type Hammer will be the best choice.

Best for: Urban construction, residential projects, and noise-sensitive environments.

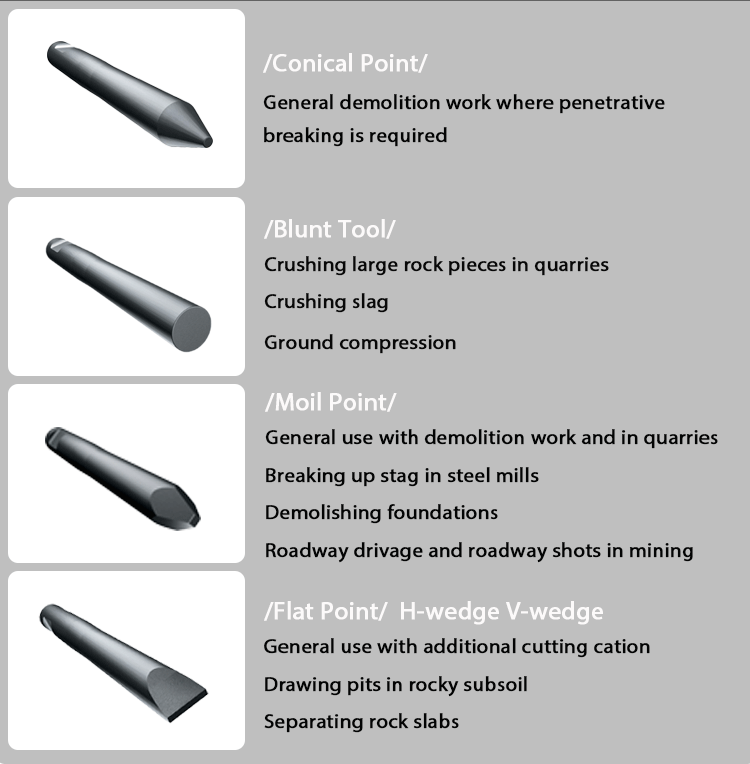

Chisel Types and Applications

Different types chisels are designed for different work. The right chisel will help your project complete well.

Excavator Compatibility

Ensuring compatibility of the hydraulic hammer for the excavator is essential for safe and efficient operation:

Conclusion:

When you choose a hydraulic hammer for your excavator, here are the guideline in short for your reference:

1, Please be clear about the project that the hammer will be dealing with.

2, Choose proper type hydraulic breaker.

3, Choose the suitable hammer model according to your excavator weight.

4, Choose the right chisel type.

5, Make sure the bracket or quick coupler could make perfect match with your excavator.

If any inquires or questions, feel free to contact with JS Attachments.